- Overview

- Product Description

- Physical Properties

- Application

- About us

Basic Info.

Model NO.

T1201

Item

Nylon Raw Material

Usage

Injection, General Plastics, Engineering Plastics

Supply Ability

800 Metric Tons Per Month

Certificates

SGS

Physical Properties

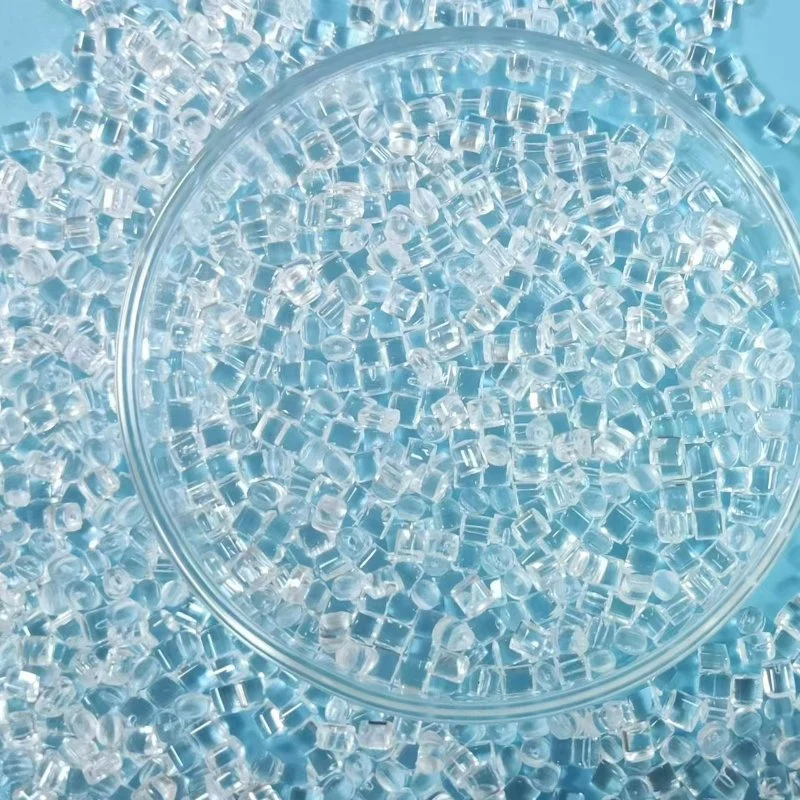

High Chemical Resistance Transparency

Features

High Strength Good Chemical Resistance

Transport Package

International Standard Package

Specification

20kg/foil bag, 1000kg/carton box

Trademark

No Mark

Origin

Shandong, China

HS Code

3908101900

Production Capacity

10000 Metric Tons Per Year

Product Description

Transparent nylon T1201 is a very cost-effective raw material used as a frame lens. The T1201 is lightweight and has high tensile and compressive strength, durability, chemical resistance, moisture resistance, impact strength and wear resistance, which can prevent the damage caused by the breakage of the glasses frame when it is impacted. Because it is synthetic plastic, the T900 is also resistant to mold, insects and fungi.

| TYPICAL PROPERTIES | CONDITION | STANDARD | UNIT | VALUE | |||

| PHYSICAL PROPERTIES | |||||||

| Density | ISO 1183 | [g/cm³] | 1.01 | ||||

| Moisture absorption | T=23°C / 50%RH | ISO 62 | [%] | 1.5 | |||

| Mold shrinkage parallel | long. | ISO 294 | [%] | 0.65 | |||

| Mold shrinkage transverse | trans. | ISO 294 | [%] | 0.75 | |||

| MECHANICAL PROPERTIES | |||||||

| Tensile modulus | 1 mm/min | ISO 527 | [MPa] | 1700 | |||

| Tensile stress at break | 50 mm/min | ISO 527 | [MPa] | 60 | |||

| Tensile strain at break | 50mm/min | ISO 527 | [%] | 150 | |||

| Flexural strength | 2 mm/min | ISO 178 | [MPa] | 65 | |||

| Flexural modulus | 2 mm/min | ISO 178 | [MPa] | 1600 | |||

| Charpy notched | +23 °C | ISO 180/1A | [kJ/m²] | 13 | |||

| Charpy notched | - 30 °C | ISO 180/1A | [kJ/m²] | 12 | |||

| Shore hardness(D) | ISO 868 | 83 | |||||

| THERMAL PROPERTIES | |||||||

| Heat Deflection Temperature | 0.45MPa | ISO 75 | [°C] | 135 | |||

| Glass-transition temperature(Tg) | DSC | ISO 11357 | [°C] | 155 | |||

| Maximum usage temperature | long term | ISO 2578 | [°C] | 90 | |||

| Maximum usage temperature | short term | ISO 2578 | [°C] | 120 | |||

| Thermal expansion coefficient long. | 23-55°C | ISO 11359 | 10-4/k | 0.9 | |||

| Thermal expansion coefficient trans. | 23-55°C | ISO 11359 | 10-4/k | 0.9 | |||

| ELECTRICAL | |||||||

| Volume resistivity | IEC 60093 | [Ω·m] | |||||

| Surface resistivity | IEC 60093 | [Ω] | |||||

| Dielectric strength | IEC 60243-1 | KV/mm | 34 | ||||

| BURNING BEHAVIOUR | |||||||

| Flammability(UL94) | 0,8 mm | ISO 1210 | [Class] | HB | |||

| Burning rate (FMVSS) | FMVSS 302 | [mm/min] | |||||

A wide range of uses,convenience and practicality.

Shandong Huachuang Special Plastic New Material Technology Co., Ltd. has a professional Specialty Nylon R & D and production team, and advanced production and testing equipment, annual output of more than 10,000 tons, the company has been engaged in the Specialty Nylon industry for nearly 20 years, providing "One-Stop Service", research and development, contract manufacturing, quality testing, packaging, sales, after-sale service, dedicated to providing customers with Special Nylon comprehensive solutions.

We produces Transparent Nylon, Bio-based Nylon, Long Carbon Chain Nylon, Barrier Nylon, Nylon Elastomer, High-Performance Nylon and other products, widely used in optoelectronic, smart wear, automobile industry, electronic and electrical, 5G communication, medical equipment, textile and clothing and other applications, exported to Europe, North America, Japan, South Korea, the Middle East, Southeast Asia and other regions.And with a number of multinational group companies to establish long-term cooperative relations.

Shandong Huachuang Special plastic new Material Technology Co., Ltd. in line with the "quality first", "customer-centric" principle, in the production and management of continuous exploration and innovation, has developed into a research and development, production, sales as one of the comprehensive enterprise.We are ready to cooperate sincerely with all sectors at home and abroad to seek win-win results and jointly create a better future for human life.

We produces Transparent Nylon, Bio-based Nylon, Long Carbon Chain Nylon, Barrier Nylon, Nylon Elastomer, High-Performance Nylon and other products, widely used in optoelectronic, smart wear, automobile industry, electronic and electrical, 5G communication, medical equipment, textile and clothing and other applications, exported to Europe, North America, Japan, South Korea, the Middle East, Southeast Asia and other regions.And with a number of multinational group companies to establish long-term cooperative relations.

Shandong Huachuang Special plastic new Material Technology Co., Ltd. in line with the "quality first", "customer-centric" principle, in the production and management of continuous exploration and innovation, has developed into a research and development, production, sales as one of the comprehensive enterprise.We are ready to cooperate sincerely with all sectors at home and abroad to seek win-win results and jointly create a better future for human life.