Basic Info.

Packaging & Delivery

Product Description

Produt Description

| Product name | Plastic Injection Molding Mold custom Plastic Power Board Plastic Electronic Components | |

| Product material | ABS, PC, PP, PS, POM,PBT,PVC,PA6,PA66,PA66+30%GF, PTFE,PC+ABS,TPE,etc | |

| Color | any colour available,will according customer's request | |

| Size | as per your drawing or the sample | |

| Tolerance | +/-0.1MM | |

| surface finish | Color painting,Texture,Silk-printing,Vacuum coating,rubber coating, etc. | |

| Logo | accept customized | |

| Application field | Various plastic injection molded parts for various industrial,electronic and automotive applications | |

| MOQ | Negotiable | |

| Mold Cavity | Single or Multi-cavity | |

| Mold life | 50000 shots -500000 shots | |

| runner system | hot runner and cold runner | |

| package | standard export carton packing ,or according your request. | |

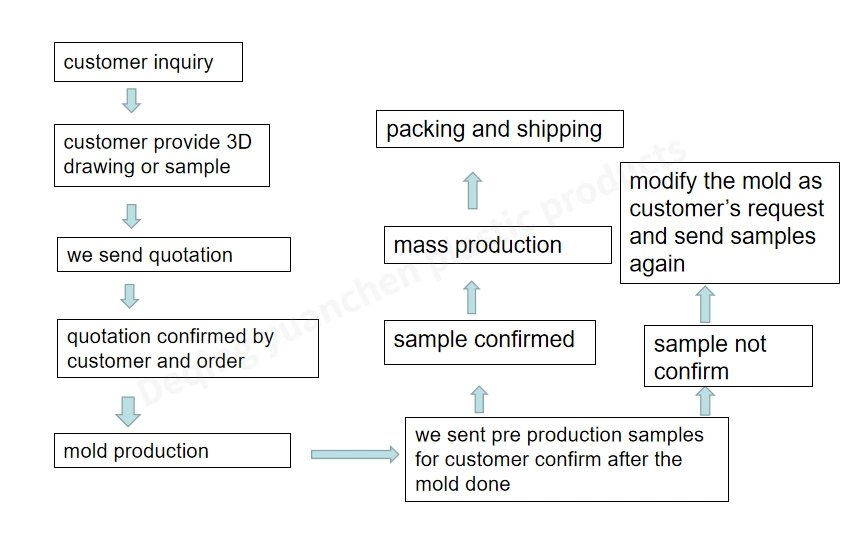

| Payment terms | For mold: 50% advanceT/T payment, balance will be after you confirm our samples; For production: 30%T/T, balance will be after received our B/L copy | |

| lead time |

|

Detailed products

Our company was founded in 2003.covers an area of 3000sqm,located in Deqing county,Zhejiang,China

we are manufacturer specialized in customized injection molding service and plastic extrusion profiles as customer's design or sample.

We provide one stop Service including prototyping of preprodcution parts,tool design and build,parts production and assembly.We have professional engineering team over 10 years experience of plastic injection mold design and plastic injection molding process.

The products made by us widely used in household electrical appliances,gym equipment ,led lamps,automotive industry,packing industry and other fields.We can customize all kinds of Engineering plastics products according to our customers' drawings or samples.

with Professional technicians and rich experience we have established solid business relationships with customers spread worldwidely,Mainly in Europe,South America and North America.

We are looking forward to forming successful business relationships with new clients in the near future.

Please feel free to contact us,We believe we will be your good business partner !

Our advantange:

1. Professional and experienced engineering and manufacturing.

2. One-stop manufacturing service

3. Custom design and size as customer requirements

4.Manufacturer: over 10 years production experience

5.Competitive Price, High quality, Fast Delivery

FAQ

Q1. Are you a trading company or a manufacturer?

We are a manufacturer.

Q2. What kind of trade terms can you do?

EX-WORKS,FOB,CIF,DDP, DDU

Q3. Can I test my idea/component before committing to mould tool manufacture?

Yes, we can make 3D samples for test functional evaluations.

Q4. Can you assure the quality ?

Yes ,We have a professional quality inspection department,pre production sample before mass production,final inspection before shipment.

Q5. Do you support OEM ?

Yes, we can produce by technical drawings or samples.

Q6.What type of plastic is best for my design/component?

Materials selection depends on the application of your design and the environment in which it will function. We are very glad to discuss the alternatives and give you best suggestions .

Q7. How about your delivery time?

Generally, it take 25 days for make mold.mass production depending on order qty.

Q8.How to slove the quality problem after sale?

please take photos&video of the problem and send us,we will make a solution for you within 24hours after we confirm the problem.

we will be responsible for our products quality.