Basic Info.

Model NO.

mult-cavity

Design Software

UG

Installation

Semi Fixed

Certification

TS16949

Standard

PUNCH

Customized

Customized

Mould Material

1.2344 Mould Steel / H13 / Bh13 / SKD61

Mould Size

230*250*261

Cavity Quantity

1*4

Transport Package

Offer

Specification

standard

Trademark

RIHA

Origin

Songjiang, Shanghai

HS Code

8480710090

Production Capacity

Customized

Product Description

We are one of the leading manufacturer in China of plastic injection parts, soft close rotary dampers, push latches and automotive interior trim parts, our products are widely used in many industries. We make customized moulds according to customer requirements, and provide one stop service from mould design, product design, injection molding to product assembly and package.

================================================================================================================

| Main Business | Customization of Injection Molds |

| Selling Point | Quality Assurance |

| Mold Material | 1.2344 Mould Steel |

| Surface Treatment | On customer requirement: |

| Product Material | Plastic |

| Certification | IATF 16949 |

| Experience | 15+ Years of Damper/Latch/Plastic Functional Parts Production 10+ Years of Plastic Injection Molding |

| Lead Time | In general: 45-60 days Special custom service: Making arrangements upon customers' request |

| Minimum Order | Comply with customer's demand |

| Packaging | Standard: Pearl cotton and bubble bag, carton box, and seal Large and big quantity: Pallet or as per customers' requirement |

| Delivery Way | On customer requirement: Express (DHL, FedEx, UPS, EMS, etc.) Standard Delivery (By Sea, By Air, or By Land) |

| Application | Auto Parts, Vehicle, Electronics, Furniture, Home Use and Household Appliances |

This plastic O-ring is one of the assembly parts of rotary damper D02025, which is applicable for some toilet seat cover, soft closing, noise reduction and shock absorption

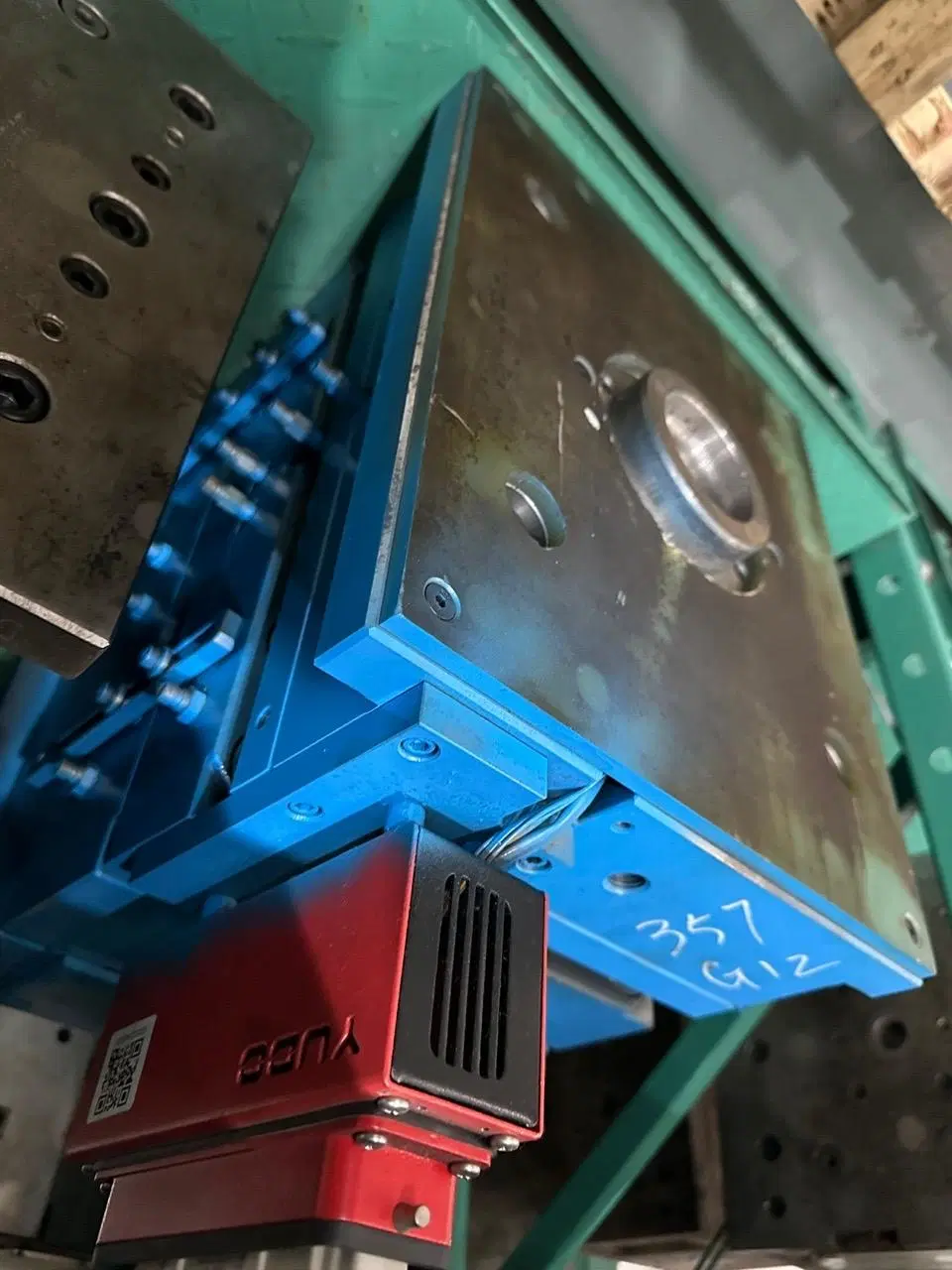

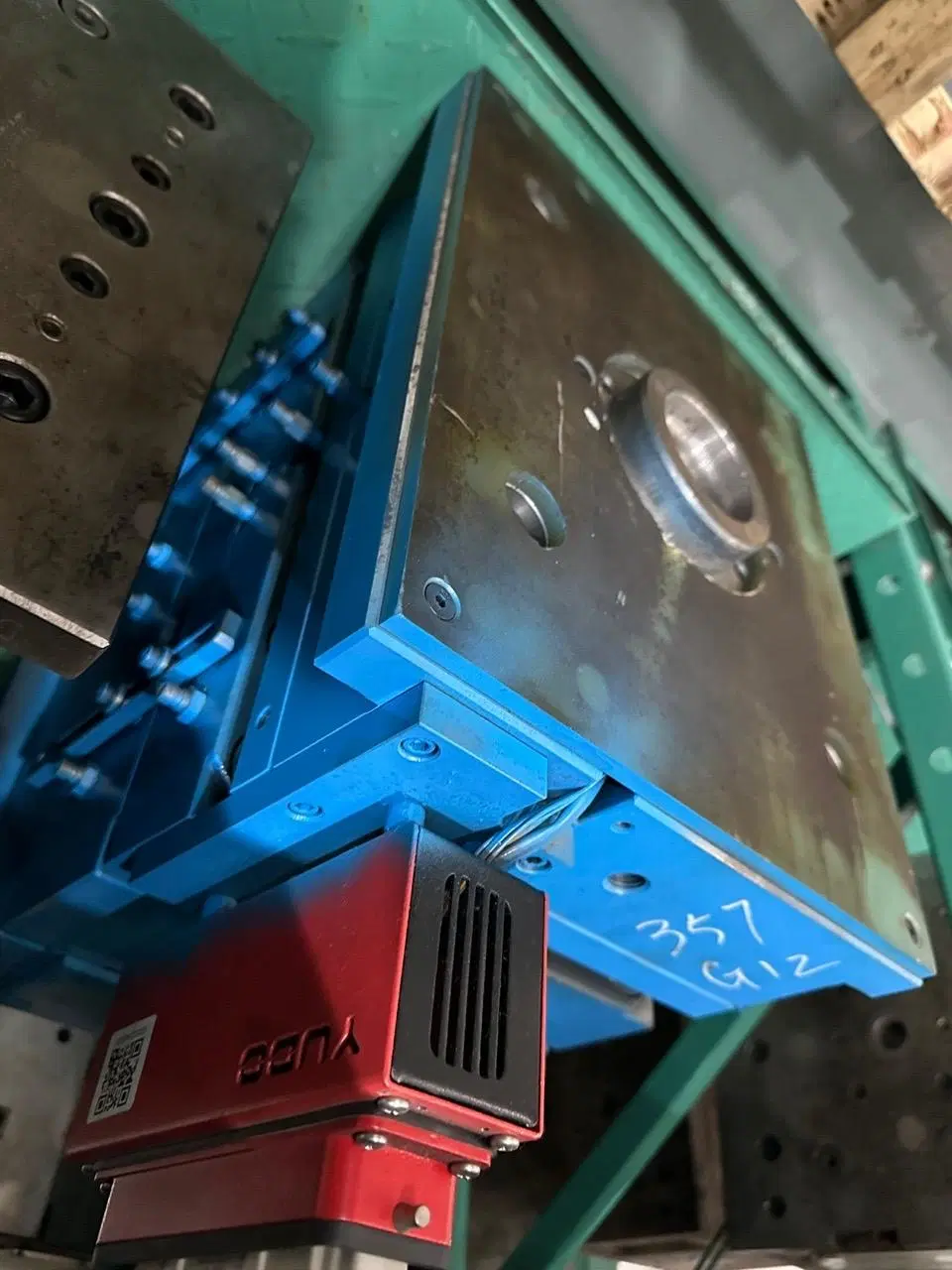

Mould picture

Square washer mould for this damper

Square washer mould for this damper

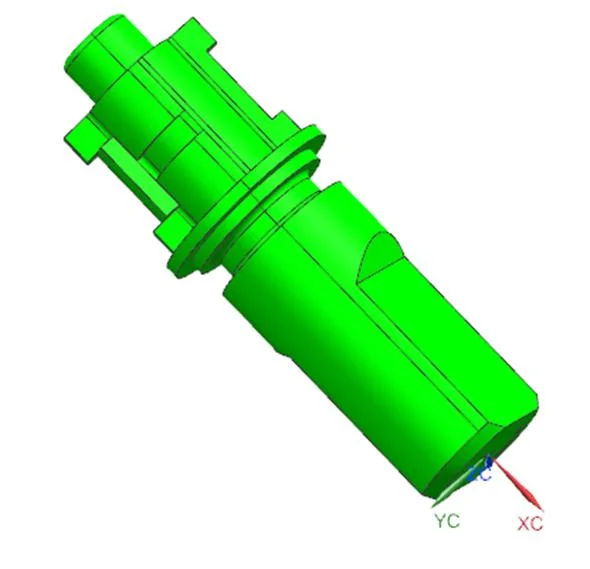

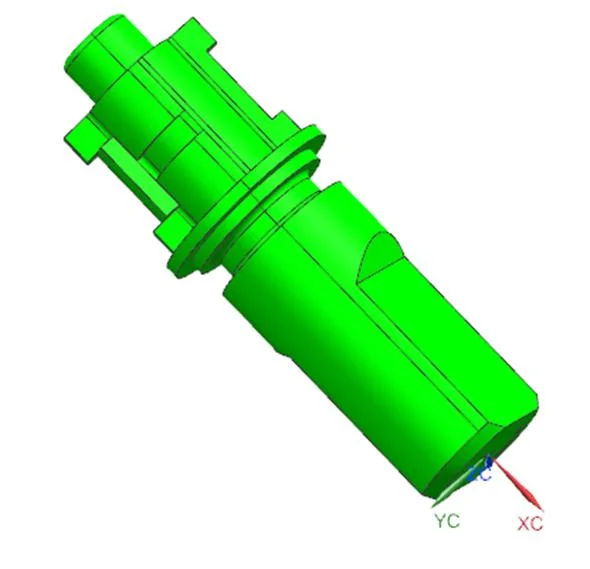

D02025 damper pictures

Similar damper - D02007 for toilet seat cover picture

Mould Picture (For damper D0200701 axis), mould size 400*320*389mm

DAMPERS

Mould Picture (For damper D0200701 axis), mould size 400*320*389mm

Our injection molds produce dampers, including rotary (gear) dampers, barrel dampers, air dampers, gear rack dampers, etc. All products are of reliable quality, with normal operating conditions from -40 ° C to 90 ° C, ensuring a minimum lifespan of 50,000 cycles. All of our molds can be customized to produce dampers according to customer needs, to realize the characteristics of high muting, miniaturization, and diversification.

Production Process

Product Design

Our experienced designers who will work with you to design your product for manufacture if required. This is a very technical area where attention to detail is vital. Expert advice is required to produce a design which is suitable for product manufacture. 3D CAD modeling and analysis, product visualization through to prototyping is all essential in this vital stage of bringing a new product to market.

As product designers, we are able to supply accurate drawings, and even a 3D representation of your product produced on 3D printers.

Tooling

Once your product design has been finalised to your complete satisfaction, it is then time to manufacture your plastic injection mould tool. Depending on the requirements of your project, our team will design and manufacture the best plastic injection moulding tool suited to your product design and production requirements.

We are able to offer you whatever grade of tooling you would like for your product, with the service to match. We are in full control of the tooling process to ensure that you receive the very best quality for the budget you are working to.

Our in-house mould tooling room has been equipped to maintain and repair the complete range of plastic moulding tools that we have supplied to our clients.

Plastic Injection Moulding

Once the tooling has been manufactured and tested, it is then time to produce your component or item.

Assembly & Packaging

So your product has now come off our conveyor belts - what next? Here we have the capability to add additional components, print on and package your product to complete the manufacture of your item. Once your product has been manufactured, we are able to assemble your item, and also complete the production cycle to final packaging, ready for distribution.

After assembling your products we can put your completed items onto our shelves for storage, ready for call off when you need them. This really is a full range service which is hard to beat. We want you to be able to concentrate on what you are good at, and leave the rest to us including the assembly and packaging!

Company Profile

| Company Name | RIHA Precision Plastic&Mold (Shanghai) Co., Ltd. |

| Location | Building 3, No. 50, Cheyang Road, Songjiang District, Shanghai |

| President | Richie Dong |

| Year of Establishment | 2013 |

| Main Business | Precision and durable molds, Precision plastic injection parts, Dampers, Push Latches, Functional parts widely used in the automotive industry and household |

| Product Range | Product development capability: provide customers with one-stop services from product structure design support, mold development, mass production, and automated assembly |

| Mold Processing Ability | MAKINO, +GF and other mold processing equipment |

| Injection Molding Ability | FANUC, Engle and SUMITOMO electric high-speed injection molding machine |

| Product Inspection Capability | Zeiss CT laser scanner, Coordinate measuring machine, Image size measuring instrument and other multi-method quality control capabilities |

Our production team includes a group of experienced and skillful technicians, and we have professional designers with high educational degree and rich experience. We use the ERP management system to monitor the whole process from design to production, ensuring product quality. In logistic and warehouse field, RIHA adopts intellectualized warehouse management, equipped with advanced robots handling automated loading and unloading. The warehouse keeper strictly follows the regulations related to intelligent logistic warehousing and code scanning system to ensure the First-In, First-Out procedure and correct placement of materials.

RIHA provides customers with one-stop product services and solutions. Under the perfect and scientific quality and management system, customers are guaranteed that the products are of high quality, low cost, and short delivery time. Our products have considerable popularity and reputation in the domestic and overseas markets respectively.