- Overview

- Product Description

- Product Parameters

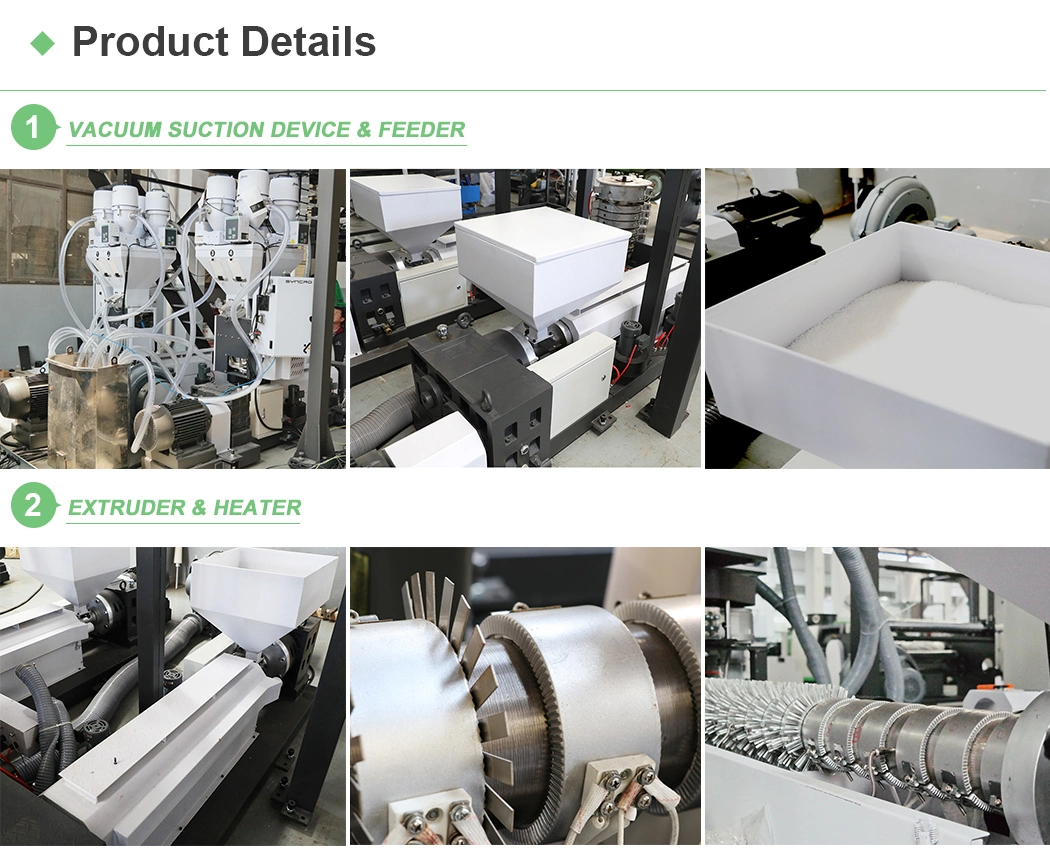

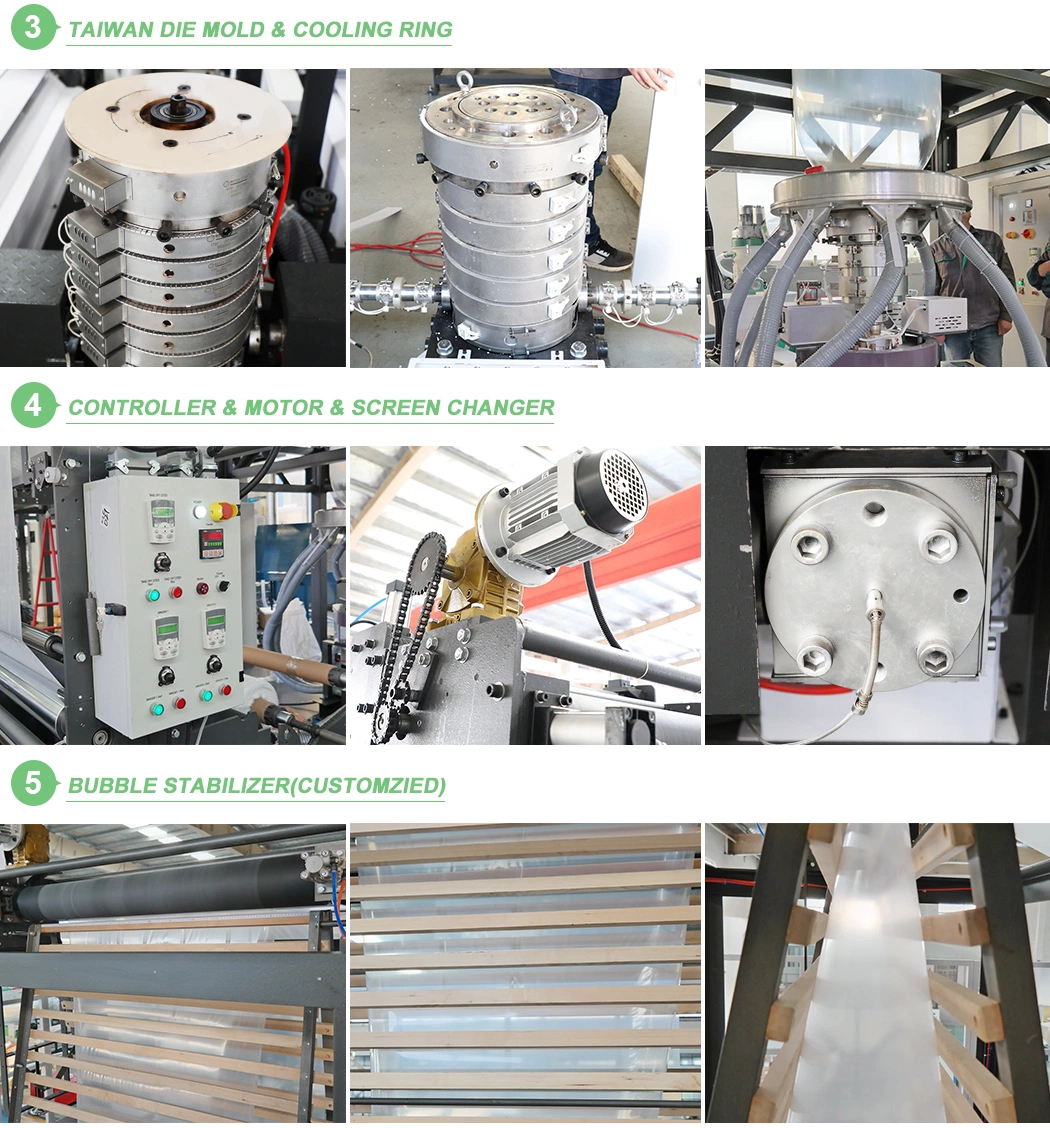

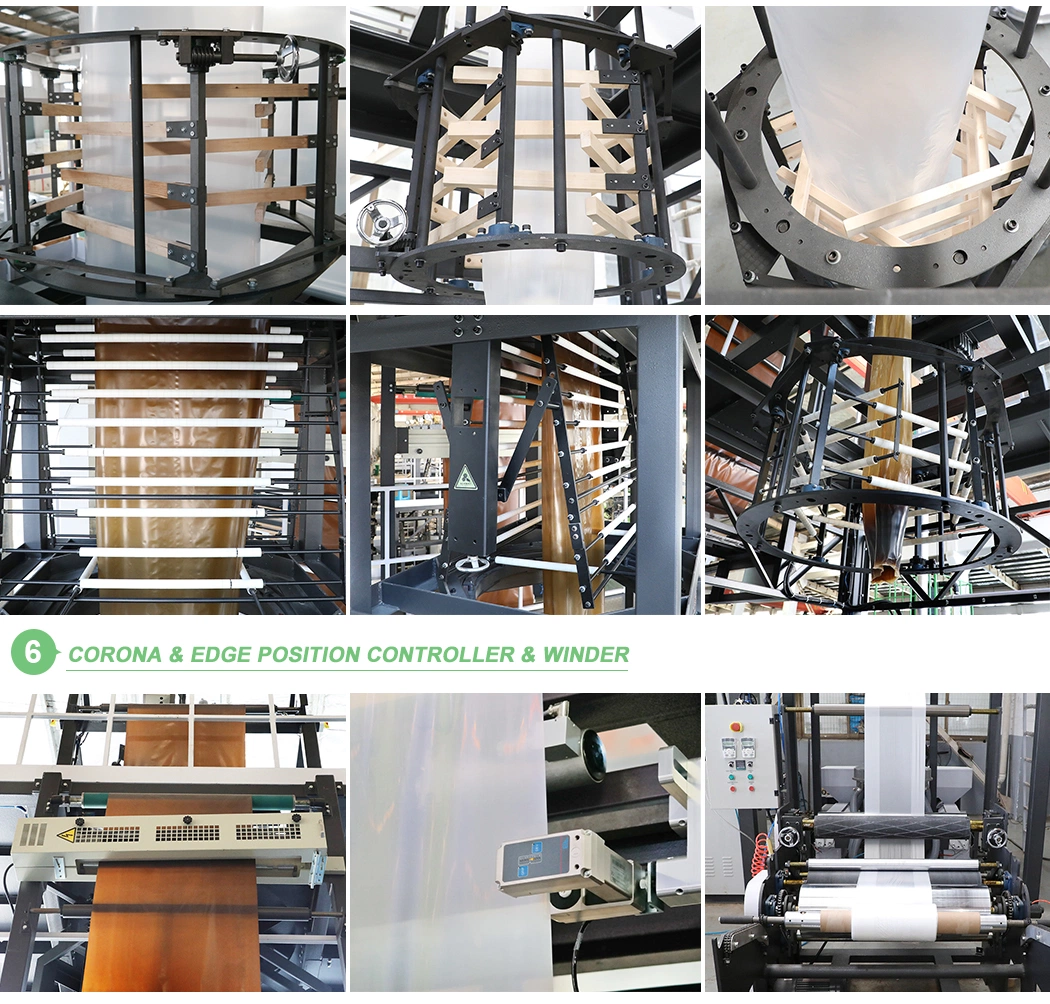

- Detailed Photos

- Company Profile

- FAQ

Basic Info.

Model NO.

CM-L45

Screw Diameter

45

Automation

Automatic

Computerized

Computerized

Machine Weight

Customzied

Certification

CE, ISO9001:2008

Machine Type

Film Blowing Machine

Electric Components

ABB, Ls, Omron, or Customized

Control

P.L.C Control

Sample/Service Manua

Available

Factory Location

2 Hours Drive From Shanghai

After-Sale Service

Free Spare Parts

Advantage

Famous Brand Motor

Business Type

Manufacturer

Material

Iron

Capacity (Kg/H)

25-50

Die Size (mm)

150

MOQ

1PC

Film Thickness (mm)

0.02-0.25mm

Transport Package

Wooden Pallet

Specification

Customzied

Trademark

ACERETECH

Origin

Jiangsu Zhangjiagang

HS Code

8477209000

Production Capacity

10 Set/Sets Per Month

Packaging & Delivery

Package Size

600.00cm * 200.00cm * 400.00cm

Package Gross Weight

4500.000kg

Product Description

Customizable Film Blow Molding Mini Machine

1.Brief introduction:

This type of film blowing machine is mainly for making T-shirt bag, packaging bag, construction film, agriculture film, lamination film etc.

Aceretech mainly focusing on R&D, manufacturing of high-end film blowing machines, provides cost-effective blown film machines and professional engineering film blowing service to markets. The typical film blowing machines Aceretech provides are: single layer blown film machines, AB double layer film blowing machines, ABA/ABC three layers blown film machines, ABCDE/ABCBA five layers film blowing machines, specialized agricultural films blowing machines and super wide industrial films making machines for materials of LDPE/LLDPE/PP/EVA/PLA/PBAT etc.

LDPE blown film machine1.Brief introduction:

This type of film blowing machine is mainly for making T-shirt bag, packaging bag, construction film, agriculture film, lamination film etc.

| Model | Roller width(mm) | Film width(mm) | Film output (kg/hr) | Main motor(Kw) | Die head(mm) | Cooling Blower(Kw) | Take up motor(Kw) |

| CM-L LD/LLDPE blown film mahine,LD:0.02-0.25mm | |||||||

| CM-L35 | 500 | 150-400 | 15-33 | 7.5 | 80 | 1.5 | 0.37 |

| CM-L45 | 800 | 400-700 | 25-50 | 15 | 150 | 2.2 | 0.75 |

| CM-L55 | 1100 | 600-1000 | 40-90 | 22 | 220 | 3.7 | 0.75 |

| CM-L65 | 1500 | 800-1350 | 60-130 | 37 | 300 | 5.5 | 1.5 |

| CM-L80 | 2000 | 1000-1800 | 120-200 | 55 | 380 | 7.5 | 1.5 |

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

* ACERETECH is original manufacturer.

* If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

* The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

SEE ACERETECH MACHINE HOW TO ENSURE THE QUALITY

* In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

* Each component before assembly needs strict control by inspecting personnel.

* Each assembly is in charge by a master who has working experience for more than 15 years

* After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF ACERETECH MACHINERY

* After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

* After the commissioning, we will package the equipment by the standard export package for shipment.

* According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.

* Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

IF YOU WOULD LIKE TO KNOW MORE ABOUT US, PLEASE CONTACT US

* ACERETECH is original manufacturer.

* If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

* The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

SEE ACERETECH MACHINE HOW TO ENSURE THE QUALITY

* In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

* Each component before assembly needs strict control by inspecting personnel.

* Each assembly is in charge by a master who has working experience for more than 15 years

* After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF ACERETECH MACHINERY

* After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

* After the commissioning, we will package the equipment by the standard export package for shipment.

* According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.

* Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

IF YOU WOULD LIKE TO KNOW MORE ABOUT US, PLEASE CONTACT US