Basic Info.

Model NO.

NWIPP

Molding Process

Injection Molding

Transport Package

Pack in Bulk

Specification

OEM

Trademark

Newayrubber

Origin

China

HS Code

3926909090

Production Capacity

500000/Month

Product Description

| Item | Core Cavity Injection Molding Manufacturing Plastic Shell Injection Mold |

| Material | ABS, PC/ABS, PP, PC, POM(Delrin), Nylon 6, Nylon 6/6, PA 12, HDPE, LDPE, PS(HIPS), Acrylic, SAN/AS, ASA, PVC, UPVC, TPE, TPR, PU, TPU, PET, PEI(Ultem), PSU, PPSU, PPE/PS, PTFE, GPPS, PPO, PES, CA, etc. If there is any special requirements on material performance, Such as Operating Temperature, UV resistance, UL standard, High transparent, Wear Resistance, Etc... If you do not know what kind of material to use, pls advise us what is the usage of these parts? Then we can make some recommend for you. |

| Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

| Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf. etc. |

| Color | Almost all PMS colors available. |

| Parameters | Inch, centimeter, millimeter, etc. |

| Function | Industrial parts /daily supply / Medical grade supply, etc. |

| Surface Treatment | Matte, Common polishing, Mirror polishing, Texture, Plating, Power Coating (Painting), Laser Engraving, Brushing, Marbling, Printing etc. |

| Mold Material | S136H, 718H, NAK80, P20, H13, etc. |

| Mold Precision | If no special request, apply to SJ/T10628-1995 standards, class 3. |

| Mold Life-cycle | 100,000-500,000 shots. |

| Sample | Available. One cavity sample mold or 3D printing. |

| Packing | Pack in bulk / poly bag / bubble bag / color box. |

| Price Tip | The price shown above is just for reference, final actual price depends on your design, material request, surface treatment, order qty, package request, etc. |

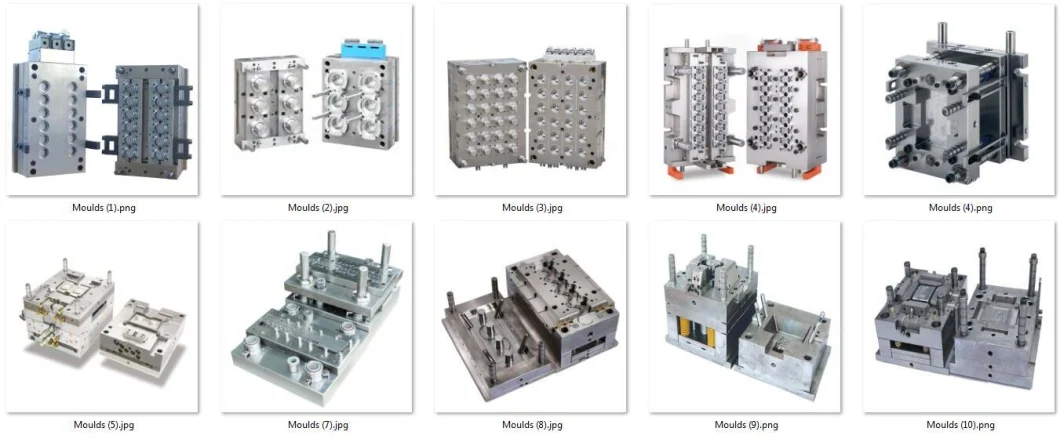

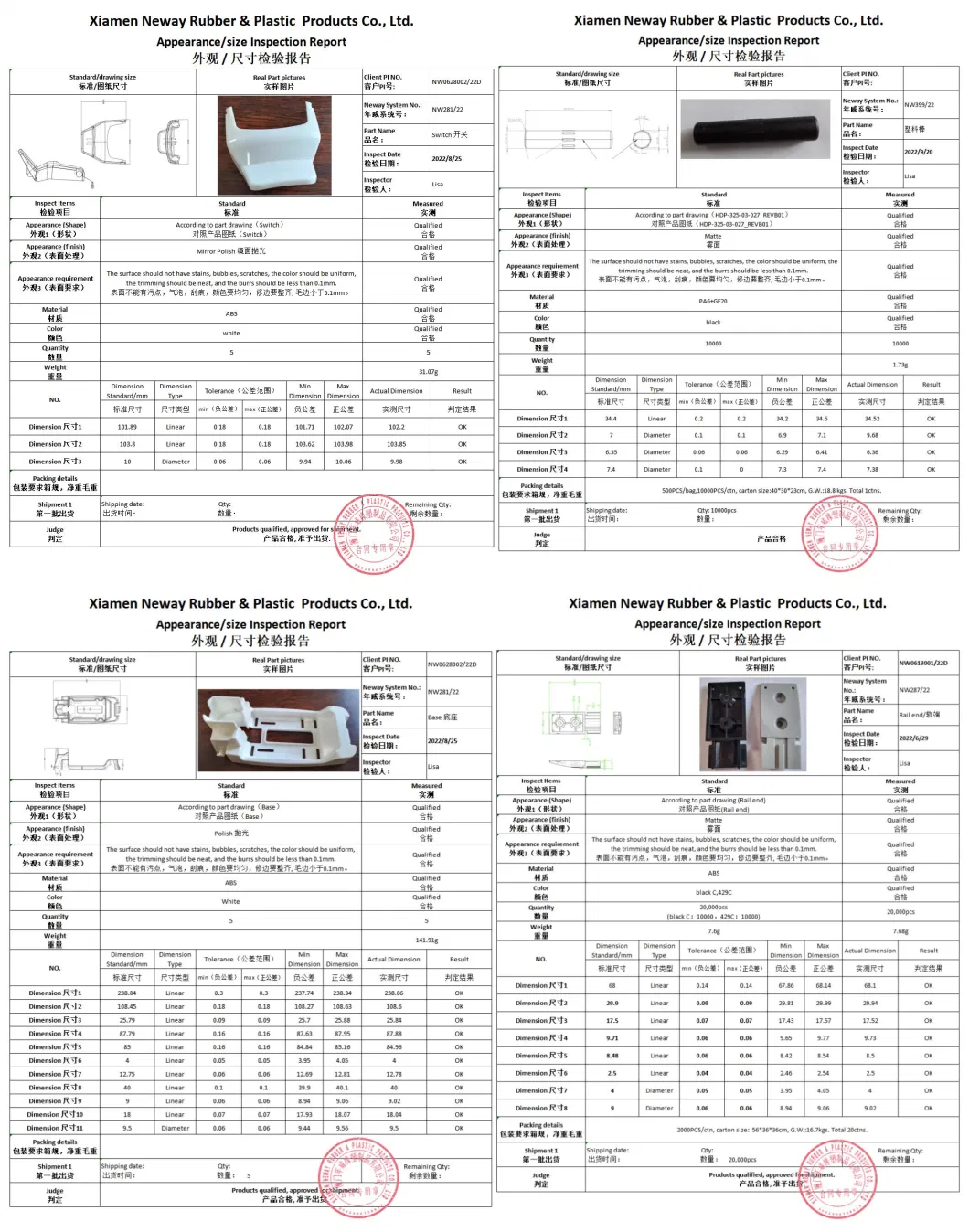

Core Cavity Injection Molding Manufacturing Plastic Shell Injection Mold

1. Rapid Prototyping & On-demand production services;

1. Rapid Prototyping & On-demand production services;

2. Professional DFM Report before Mould Making;

3. Capability for plastic injection molding is up to 1500mm

3. Capability for plastic injection molding is up to 1500mm

DFM Report (Design for Manufacturability) for Reference.

Some Custom Plastic Parts for Your Reference.

Neway Highly Welcome Your Own Custom Designs !!!

Neway Support Custom Design Moulds & Moulds Export.

Neway Can Also Provide Mould Spare Parts Export, eg: Slider, Inserts, Ejector Pins, etc.

NEWAY has complete production chain from R&D, Rapid Prototypes, mould design, mould making, components production, assembling, packing to export.

Having one supplier like Neway for the complete assembly will allow for better design, quality, and fit of all the individual parts.

NEWAY has complete production chain from R&D, Rapid Prototypes, mould design, mould making, components production, assembling, packing to export.

Having one supplier like Neway for the complete assembly will allow for better design, quality, and fit of all the individual parts.

The most common used surface treatment are: Matte, Texture (fine texture, rough texture...), Common Polishing, Mirror Polishing, Laser Engraving, Printing, Plating, Brushing, Marbling), etc. You can view below surface pictures for reference:

The most common used surface treatment are: Matte, Texture (fine texture, rough texture...), Common Polishing, Mirror Polishing, Laser Engraving, Printing, Plating, Brushing, Marbling), etc. You can view below surface pictures for reference:

Company Profile

Good reviews of customer

NEWAY dedicated to strict quality control and thoughtful customer service. We strive to exceed our customers' expectation in all aspects of product manufacturing process, and recognize our great responsibilities to our customers.

All our materials are purchased from certified suppliers. All materials will be subject to warehousing quality inspection upon arrival. After the pre-production sample is confirmed, the sample will be sealed immediately. prenatal sampling inspection, intrapartum sampling inspection, and postpartum sampling inspection, and the inspection results will be recorded in time. All files are traceable.

Below are some inspection equipment for reference:

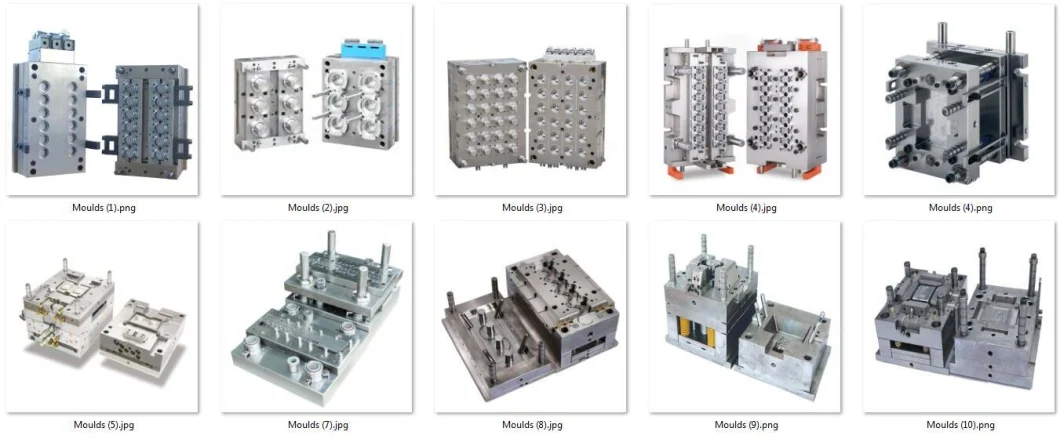

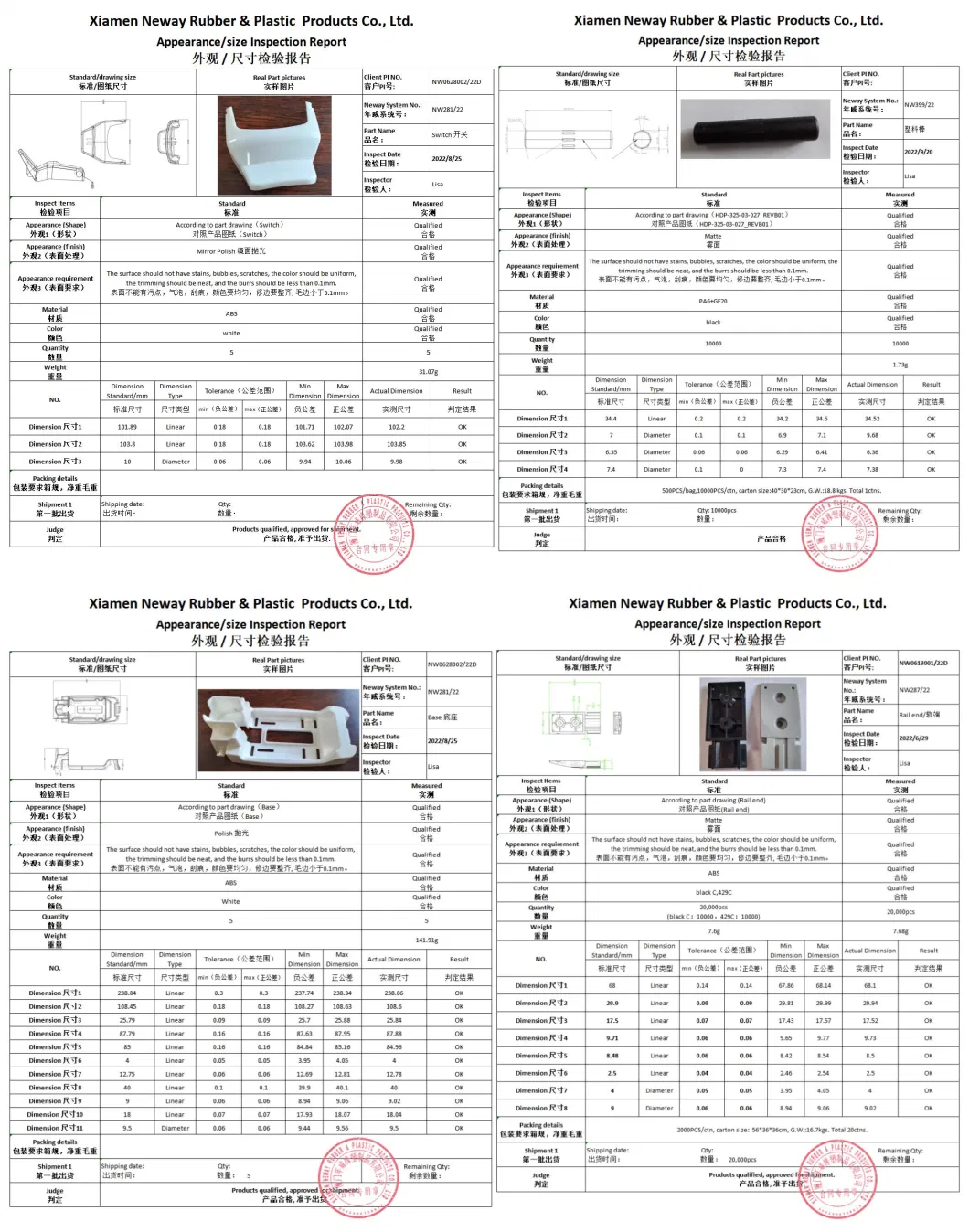

And attach the injection molding plastic parts inspection report for reference:

NEWAY's package for plastic prototypes: pack in bulk, poly bag, gift box, blister box, or special custom package request according to customers.

NEWAY's package for plastic prototypes: pack in bulk, poly bag, gift box, blister box, or special custom package request according to customers.

NEWAY's package for plastic prototypes: pack in bulk, poly bag, gift box, blister box, or special custom package request according to customers.

NEWAY's package for plastic prototypes: pack in bulk, poly bag, gift box, blister box, or special custom package request according to customers. All goods shipped by sea are packed with pallets, all goods shipped by express/air are packed with nylon straps. Wooden boxes are used for heavy goods. All cartons have passed the box drop test to ensure that the products received by customers are in good condition.

FAQ

FAQ

Q1. How soon can I get a precise quotation for plastic injection part? A1: Please send us your inquiry by email or Alibaba TM message. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance.

Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.

Q4: What does your OEM service include?

A4: We follow up your request from the design idea to the mass production.

a. You can provide 3D drawing to us, then our engineers and production teams evaluate the design and quote you the precise cost.

b. If you don't have 3D drawing, you can provide 2D drawing or draft with features details with full dimensions, we can draft 3D drawing for you with fair charge.

c. You can also customize Logo on the product surface, package, color box or carton.

d. We also provide assembly service for the OEM parts.

Q5. What is your payment term?

A5: We accept T/T, Paypal, Western Union, L/C, Alibaba Trade Assurance.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.

Q4: What does your OEM service include?

A4: We follow up your request from the design idea to the mass production.

a. You can provide 3D drawing to us, then our engineers and production teams evaluate the design and quote you the precise cost.

b. If you don't have 3D drawing, you can provide 2D drawing or draft with features details with full dimensions, we can draft 3D drawing for you with fair charge.

c. You can also customize Logo on the product surface, package, color box or carton.

d. We also provide assembly service for the OEM parts.

Q5. What is your payment term?

A5: We accept T/T, Paypal, Western Union, L/C, Alibaba Trade Assurance.

Work with Neway, your business is in safe and your money is in safe.

If you can dream it, we can build it!