Basic Info.

Model NO.

YHC1

Speed

Adjustable

Energy Saving

70%

Data Saving

20 Sets

Speed,Force, Stroke

Adjusted on Touch Screen

Type

C Type Hydraulic Press

Certification

ISO9001, CE, BV

Transport Package

Export Special Wooden Case

Specification

1500*1680*3620mm

Trademark

YIHUI

Origin

China

HS Code

8462919000

Production Capacity

400 PCS / Year

Product Description

c frame injection molding hydraulic press with servo system CE

We are the factory specializing in the production of hydraulic presses.

And can provide total solutions, including hydraulic press machines, molds, product processing technology, automated production lines.

YIHUI C frame servo hydraulic press machine with PLC and with touch screen and with servo motor .

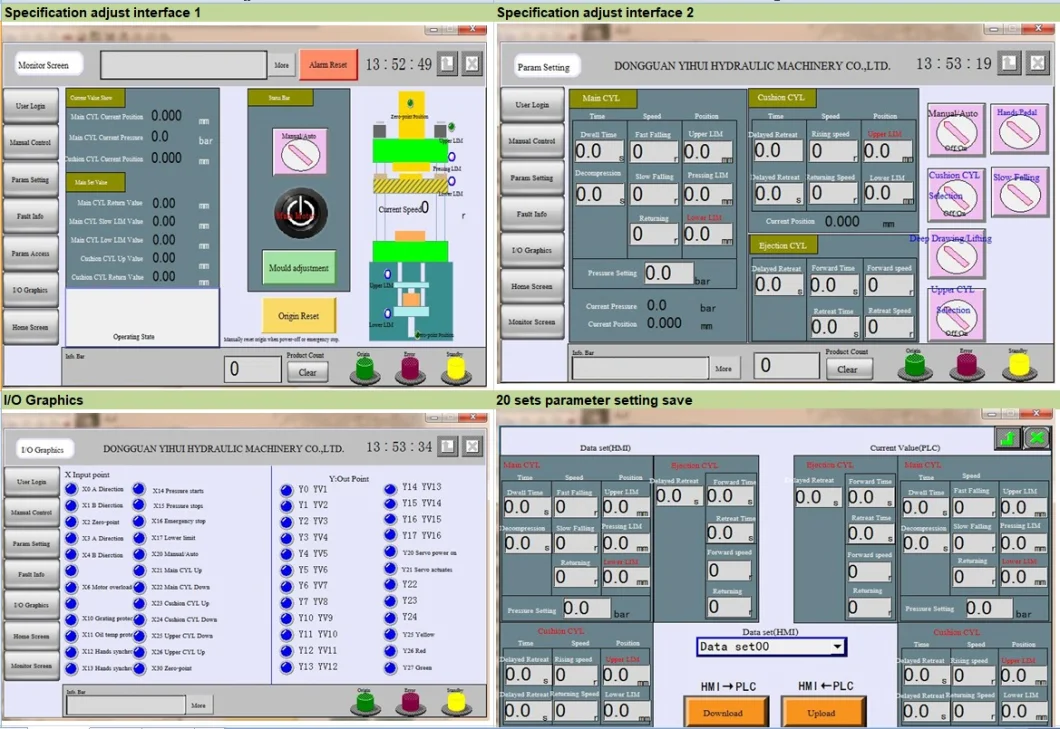

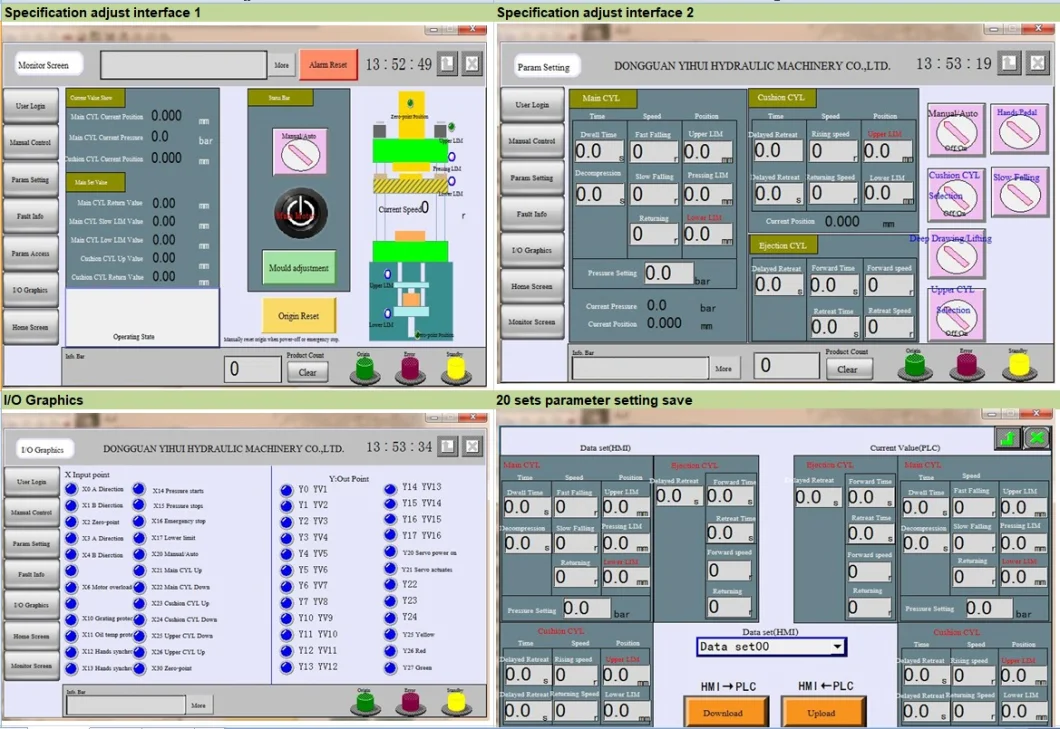

Touch Screen Details

Product Application

1) Pressing, Forging, Stamping, Powder Compacting, Compressing, Moulding and so on.

2) Stamping and riveting bearing, and other metal parts etc.

3) Molding and stamping for metallic and non-metallic.

Parameters

We are the factory specializing in the production of hydraulic presses.

And can provide total solutions, including hydraulic press machines, molds, product processing technology, automated production lines.

YIHUI C frame servo hydraulic press machine with PLC and with touch screen and with servo motor .

Touch Screen Details

Product Application

1) Pressing, Forging, Stamping, Powder Compacting, Compressing, Moulding and so on.

2) Stamping and riveting bearing, and other metal parts etc.

3) Molding and stamping for metallic and non-metallic.

Parameters

| YHC1 C frame hydraulic press specificaiton | ||||||||

| Item | Unit | Specification | ||||||

| YHC1-30T | YHC1-50T | YHC1-80T | YHC1-100T | YHC1-150T | YHC1-200T | |||

| Nominal Force | kN | 300 | 500 | 800 | 1000 | 1500 | 2000 | |

| Max.Working Pressure | Mpa | 19 | 20 | 21 | 20 | 21 | 21 | |

| Master Cylinder Nominal Force | kN | 300 | 500 | 8000 | 1000 | 1500 | 2000 | |

| Max.Stroke of Ram | mm | 300 | 350 | 450 | 450 | 450 | 450 | |

| Daylight (Max.Open Height) | mm | 500 | 550 | 600 | 700 | 700 | 700 | |

| Speed of Ram | Down No Load | mm/s | 250 | 205 | 190 | 190 | 190 | 190 |

| Pressing | mm/s | 20 | 22 | 20 | 20 | 20 | 20 | |

| Return | mm/s | 230 | 200 | 185 | 180 | 180 | 180 | |

| Effective Area of Working Table | RL(Edge) | mm | 400 | 450 | 500 | 600 | 600 | 600 |

| FB(Edge) | mm | 300 | 350 | 300 | 380 | 380 | 380 | |

| Upper Shank Size | mm | φ50*70 | φ50*70 | φ60*75 | φ60*75 | φ60*75 | φ60*75 | |

| Effective Area of Working Table | RL(Edge) | mm | 600 | 700 | 800 | 900 | 900 | 1000 |

| FB(Edge) | mm | 460 | 500 | 550 | 600 | 600 | 600 | |

| Overall Dimension | L.R | mm | 940 | 1040 | 950 | 1150 | 1150 | 1150 |

| F.B | mm | 1320 | 1540 | 1750 | 1840 | 1950 | 2150 | |

| H | mm | 2060 | 2300 | 2540 | 2580 | 2670 | 2770 | |

| The Distance Between the Working Table and the Ground | mm | 800 | 800 | 800 | 900 | 900 | 900 | |

| Servo Motor Power | kW | 6 | 11.6 | 16.4 | 16.4 | 16.4 | 16.4 | |

| Total Weight(Approx) | kg | 2350 | 2610 | 5000 | 6500 | 12000 | 15000 | |

| Oil Quantity(Approx) | L | 120 | 130 | 200 | 270 | 270 | 270 | |

All above specifications are standard sizes of hydraulic press machine,any special specifications customize is also available for us!

Component Details

Why so many famous brand company cooperate with us ?

1.Our factory have specialized in independent development and producing hydraulic press for 20 years.So the product is stable and high quality.

2. Machine body, we use bending structure , much stronger than the common welding structure .

3. Oil pipe, we use Clip-on structure , much tight than common welding structure. Prevent oil leakage.

4. We take integrated oil manifold block, much easier to check machine and repair machine.

5.The main components are imported from Germany, Italy and Japan . So the quality is near the Japan production, but the unit price is lower than Japan production.

6.Our factory can offer full set line service, such as the mould,process technology, and other relative machines.

Our Certificates

Features:

Servo motor drive system:

1. Small start-up current: little impact on power grid.

2. Motor starts when press is punching and stops when feeding material,picking out bricks,and cleaning mould. Energy-saving high to 65%.

3. High control precision: speed error is only 0.0001/r.

4. Stable running: no vibration and high torque when runs with low speed.

5. Quick response: very short time from static to rated speed, able to adjust speed freely between high speed to low speed within one stroke. Excellent effect of even hammer strike.

6. Speed overload function, achieves 2-3 times of rated speed.

Touch screen parameter setting system:

1. According to technology demands for different bricks, user can set the strike times, strike strength, and strike speed digitally. Able to achieve the effect of gently press for air-released, strike from gentle to heavy, the whole process of brick producing sequencing, reduce human factor to improve product quality.

2. Touch screen can real-time display the working status, monitor the producing process, detect and report the failure automatically.

3. Able to set password to protect production safety.

4. Touch screen has operation instruction and guideline.

Customer Visit

YIHUI Hydraulic press with servo system,can bring you 10 kinds Advantages as below:

1. Can avoid the oil leakage. Because using Servo motor, the oil temperature can be lower.

2. English and customer country local language, bilingual operation interface, easy to operate.

3.Can save 50% - 70% energy.

4.Parameters and Speed can be adjusted on the touch screen, easy to operate.(Machine without servo system, speed can not been adjusted.)

5.Can be 3 to 5 years longer service life than the common machine.

it means,if common machine can service for 10 years, then machine with servo, can use 15 years.

6.Ensure safety and easy to know error,easy to do after service. Because of Automatic alarm and auto troubleshooting system.

7.Very easy to change mold, shorter time of changing mold.

Because it have memory function,if use the original mold, do not need to adjust parameter again,

8.Very quiet , do not have noise.

9.Much stable than common machine.

10.Much high precision than common machine.

Our Company

Years of Experience

Dongguan Yihui Hydraulic Machinery Co., Ltd. has been specialized in manufacturing hydraulic press machine for over 20 years . Especially speciallized in the servo system hydraulic press machine .

Exported Countries

YIHUI brand machines have been exported to over 40 countries,

such as Germany, USA, UK, Sweden, Japan,Slovenia, Serbia,Saudi Arabia,El Salvador,Togo, Malaysia,Singapore, Australia ,Vietnam,Pakistan,South Africa, and so on.

Cooperative brand

Customers' Positive Feedback

Exhibition

Packing&Delivery

| Packing | |

| Size | Accordingly |

| Weight | Accordingly |

| Packing Details | The normal package is wooden case(Size: L*W*H). The wooden case will be fumigated if needed. If container is too tight, we will use PE film for packing or pack it according to customers' special request. |

FAQ

Q1. Are you manufacturer or Trader?

A1: We are professional in producing hydraulic press for over 20 years, We have our own designer,and the machines have been patented.

Q2. How to get an accurate quotation?

A2: The customer should provide the related technical requirements, product drawings, pictures, industrial voltage, planned output, etc.

Q3. What if I use this machine for the first time and know nothing of it ?

A3: We will have our engineers teach you how to operate it,you can just inform us some details of the product.you need then we can customize as your special order.

Q4. How does your factory do regarding quality control?

A4:Dongguan YIHUI has been regard quality as the priority. We always attach great importance to quality controlling from the very beginning to the very end ,so our press can match all the CE and ISO standard also more strict standard .

Q5. How about your delivery time?

A5: Generally, it will take 35 days after receiving your deposit payment. The customized press delivery time depends on the items and the quantity of your order, in general is 55 days.Sometimes we have standard machines in stock.

Q6. What is the warrantee period of the machine?

A6: We can supply 1 year warranty for our machines, We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

Q7. What is the after-sales service of your factory?

A7: 1.Installation:Free installation and commissioning, travel expense is on foreign customer. (Including round ticket and accommodation cost)

2.Personnel training: Our engineers will give your employees free machine training when they come to our company to assemble the machines, and welcome to our factory to learn how to operate our machine.

B7: And we can offer engineer overseas service.

Q8. What is the advantage of your factory?

A8: The main components of our machine are imported from the famous brand such as Japan and Germany. So the quality is near the Japan production, but the unit price is lower than it.

We do have a full set line service (turnkey project),which means that we can not only provide the press and mold but also able to customized as your special order.